The existing research infrastructure is valued closed to 6.5 M Euros and consists in over 20 research equipment with an individual value of more than 100,000 Euros considered fundamentally for increasing the ICSTM of VUT chances of absorbing funds from:

- national and international CDI projects

- the institutional development fund (CNFIS-FDI)

- contracts with other universities, institutes, agencies, organizations and economic agents.

The certified/accredited research equipment from the ICSTM endowment is presented in detail on the platform https://eeris.eu/ERIF-2000-000Y-0122 and https://916.icstm.ro/.

Stereomicroscope STEMI 2000-c

- Zeiss

- 2014

The Stemi 2000-c stereo microscope is completely customizable, the trinocular viewing head allowing the possibility of attaching a video camera for capturing images/video in real-time. The microscope’s eyepieces have a visual field of 10x / 23 mm and the magnification steps are between 0.65x and 5x, thus allowing to reach a variable magnification range between 6.5x and 50x. The microscope mechanism allows the modification in steps (by click) of the magnification settings as follows: 0.65, 0.8, 1.0, 1.25, 1.6, 2.0, 2.5, 3.2, 4.0 and 5.0. This model can be used successfully both in biotechnology and medical technology, as well as, in technology, materials science, or the study of semiconductors etc.

Printed Circuit Board Prototyping Line

- LPKF

- 2014

PCBs offer both mechanical and electrical support for connections between electronic components. The PCB line gives the possibility of having a complete functional electronic circuit, starting from the basic design of the electronic circuit, in a CAD program, till the final stage of testing its electric and electronic functionality.

Oxidation Stability Tester – PetroOxy

- Anton Paar

- 2014

PetroOxy has been developed as a testing device for the oxygen stability, of commercially available fuels stability. The patented Rapid Small Scale Oxidation Test (RSSOT) provides a complete oxidation stability analysis of petroleum products, automatically in a very short test time. The results include all volatile and nonvolatile oxidation products, providing a comprehensive analysis of the sample.

FORM 1 Stereolithography Machine Rapid Prototyping

- FORMLABS

- 2014

The equipment builds 3D parts made of liquid photopolymer resin. Stereolithography or SLA is a 3D printing technology consisting in a process of optical fabrication by photo-solidification of liquid resins used to produce models or small prototypes.

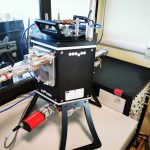

Installation for thin film deposition in vacuum with electron beam (E-BEAM)

- Mantis Deposition LTD

- 2015

HEX MANTIS Deposition LTD is a modular system for submitting metal and dielectric thin films in high vacuum. SPECIFICATIONS: • Quick change of deposition sources without having to use tools; • Quartz microbalance with (QCM) and independent shutters from sources and sample holder with the size of 100 mm, which allow highly accurate thin films up to monolayer and sub-monolayer; • An electron beam evaporator in vacuum, with 32 mm diameter, water-cooled and electronic control of software for monitoring the flow rate control; • Power supply 250W, with bar evaporation and crucible without requiring hardware changes; • A crucible Molybdenum volume 390 mm3 and a Molybdenum connector for bar evaporation; • The turntable that sits the sample contained cooling water to allow the deposition of metal films on a polymeric substrate (lift-off procedure) for processing samples lithographed; • Turbomolecular pump capacity 80 l/s; • Software that allows programming sequences for submission by the user from the computer; • The rate of deposition evaporator to 100mm distance: submonolayer/min ≈ 5 nm/min from the bar and ≈20 nm/min from the crucible; • An automatic shutter for the flow of electrons and one for QCM; • Quartz system for independent monitoring of deposits, measurement resolution deposits is 0.1Angstrom; • Electronics for power and control of deposits (temperature, pressure, layer thickness).

Characterization System Module And Solar Cells ORIEL SOL3A CLASS AAA SOLAR SIMULATORS part of Testing and characterization cells photovoltaic labo

- Newport

- 2014

The Oriel Sol3A simulator use a single lamp design to meet not one or two, but all three performance criteria without compromising the 1 Sun output power, providing true Class AAA performance. Oriel Sol3A also integrates a partial sun attenuating device to allow easy variation of the output from .2 – 1.0suns with the simple turn of a knob. The Oriel Sol3A uses a black non-reflective finish to minimize stray light, incorporates captive screws for all panels requiring user access to facilitate lamp replacement, alignment, and filter changes, and incorporates safety interlocks to prevent inadvertent exposure to UV light.

Installation for thin film deposition by spinning (SPIN-ON)

- MTI-XTL USA

- 2015

VTC-100A is a optimal equipment for deposition of layers on different surfaces by spinning. The device is compact, the sample it is mounted on the support by of vacuum and this equipment is used for sol-gel deposition on substrates of up to 100 mm in diameter. Specifications: • Aluminum casting case to keep spinning stable; • Disk made of Polypropylene (PP) to resist most of the corrosive solutions; • Drainage outlet and vacuum pump connector are on back panel; • Chamber diameter: 225 mm.

ORIEL INSTRUMENT’S IQE-200 MEASUREMENT SYSTEM

- Newport

- 2014

Oriel Instrument’s IQE-200 system allows the measure of External Quantum efficiency (EQE) also known as Incident Photon to Charge Carrier Efficiency (IPCE) as well as Internal Quantum Efficiency (IQE) for solar cells, detectors, or any other photon-to-charge converting device.

Installation for thin film deposition by sol-gel coating (DIP COATER)

- NADETECH

- 2015

The Nadetech ND 3D Multi Axis Dip Coater is an optimal equipment for the deposition of layers on different surfaces through different deposition techniques such as Layer-by-Layer assemblies, Sol-gel coatings, or Self-assembled monolayers. The ND-3D Coater enjoy a 2 axis programmable system. One axis is for vertical displacement and the other for movement in the horizontal plane. This configuration offers a high versatility for multistep deposition which requires the consecutive immersion in vessels with different solutions in a higher space. The range of immersion and dipping-out speed is very broad, from a minimum speed of 0,6 millimeter per minute to a maximum of 1000 mm per minute. The vertical axis has a maximum displacement of 250 mm and the horizontal axis may work in an area of 500 x 200 mm. Depending on the volume and size of the vessels or trays arranged for the deposition cycles, multi-step immersions in different solutions can be programmed in a single work cycle. Technical specifications: – Vertical displacement: 200 mm – Horizontal displacement: 500×250 mm – Minimum Dipping Speed: 0,6 mm/min – Maximum Dipping Speed: 1000 mm/min – Maximum weight sample: 1500 g.

FLUKE TI400 THERMAL IMAGER

- FLUKE

- 2014

Standard infrared lens and autofocus with technology LaserSharp; temperature range : -20 ° C and 1200 ° C; thermal sensitivity: ≤ 0.05 ° C at a target temperature of 30 ° C; resolution: 320 x 240 (76,800 pixels); spatial resolution: 1.31 mRad; field of view: 24 ° horizontal x 17 ° vertical.